Technical Specification for Synthetic Piezoelectric Quartz Crystals.

All tests of quartz quality are made according to IEC 60758(2016) Standard

1. Modification: Right-Hand (RH).

2. Q-value Q≥1,8х106

3. Grade of inclusions density is shown in Table 1 .

Table 1.

| Grade | Inclusions density, no more, pcs./cm3 | |||

| (10-30) mkm | >(30-70) mkm | >(70-100) mkm | > 100 mkm | |

| Ib | 3 | 2 | 1 | 1 |

| I | 6 | 4 | 2 | 2 |

| II | 9 | 5 | 4 | 3 |

4. Grade of etch channel density is shown in Table 2

Table 2

| Grade | Etch channel density, pcs./cm2 |

| 1 | 10 |

| 2 | 30 |

| 3 | 100 |

| 4 | 300 |

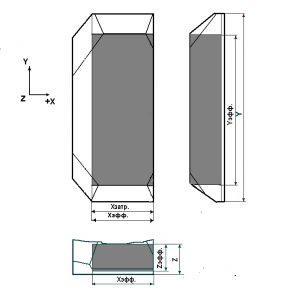

5. Crystals’ dimensions

5.1 Along Y-axis ≥ 200 mm

5.2 Along Х-axis – not less 70 mm

5.3 Along Z-axis ( Z eff. as per IEC 60758)– should correspond to dimensions in table 3. The dimension along Z-axis is the minimum thickness dimension of the crystal.

Table 3.

| Mark of the group when ordering | Z eff, mm |

| 2.10 | От 23 до 32,9 вкл. |

| 2.15 | От 33 до 42,9 вкл. |

| 2.20 | form 43 to 52,9 including. |

| 2.25 | from 53 to 62,9 including. |

| 2.30 | from 63 to 72,9 including. |

| 2.35 | from 73 to 82,9 including. |

| 2.40 | from 83 to 92,9 including. |

| 2.45 | from 93 to 102,9 including. |

| 2.50 | from 103 and more |

6. Seed specification.

6.1 Surface XY orientation towards axes X and Y –0+/- 30’

6.2 Seed dimension along Z-axis in a grown crystal – no more than 2,0 mm.

6.3 Dimension along Х- axis 67 mm and more

6.4 The following is permitted: non-rectangular shape, minimum prisms’ dimension > 60 mm (should be specified before ordering);

7. Twins, punctures and cracks in Z-zone of the crystals are not allowed.

8. Crystals may have:

The permitted defects of external view are specified when ordering.

9. Marking.

Should be specified before ordering.

10. Packing.

Packing should provide the crystals’ safety during transportation.

Technical Specification for One-side Synthetic Quartz Crystals.

All tests of quartz quality are made according to IEC 60758(2016) Standard

1. Product name: One-side Synthetic Quartz Crystals.

2. Modification: Right-Hand (RH).

3. Q-value Q≥1,8х106

4. Grade of inclusions density is shown in Table 1 .

Table 1

| Grade | Inclusions density, no more, pcs./cm3 | |||

| (10-30) mkm | >(30-70) mkm | >(70-100) mkm | > 100 mkm | |

| Iа | 2 | 1 | 0 | 0 |

| Ib | 3 | 2 | 1 | 1 |

5. Grade of etch channel density – no worse the grade (see table 2)

Table 2

| Grade | Etch channel density, pcs./c22 |

| 1 | 10 |

| 2 | 30 |

| 3 | 100 |

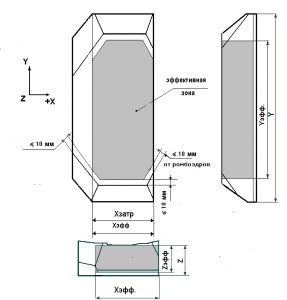

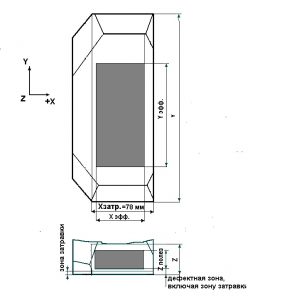

6. Dimensions:

along Z-axis – not more than 23 mm ;

along Y-axis – not more than 200 mm

Z eff., Z usable, Х eff.,Y eff. – drawings 1,2,3.

Crystals’ dimensions along Z-axis are specified when ordering.

7. Seed:

7.1 Dimensions:

along X-axis of seed =80+/-2 mm;

along Z-axis in block – no more 2 mm

along Y-axis – not less 200 mm

7.2 Surfaces’ orientation tolerances

| – Х-surface towards axes YY´ and ZZ´ | 0º 00´ +/- 15´ |

| Z- surface towards axes XX´ and YY´ | 0º 00´ +/- 30´ |

8. Defects

Optical and electrical twins, punctures and cracks in effective (usable) zone are not allowed (dwg.1,2,3)

The permitted defects of external view are specified when ordering.

9. Peculiarities

Mechanical treatment of all surfaces is permitted.

10. Marking

Marking on seed surface includes: batch №

11. Packing

Packing is made in cartons and should provide the crystals’ safety during transportation.

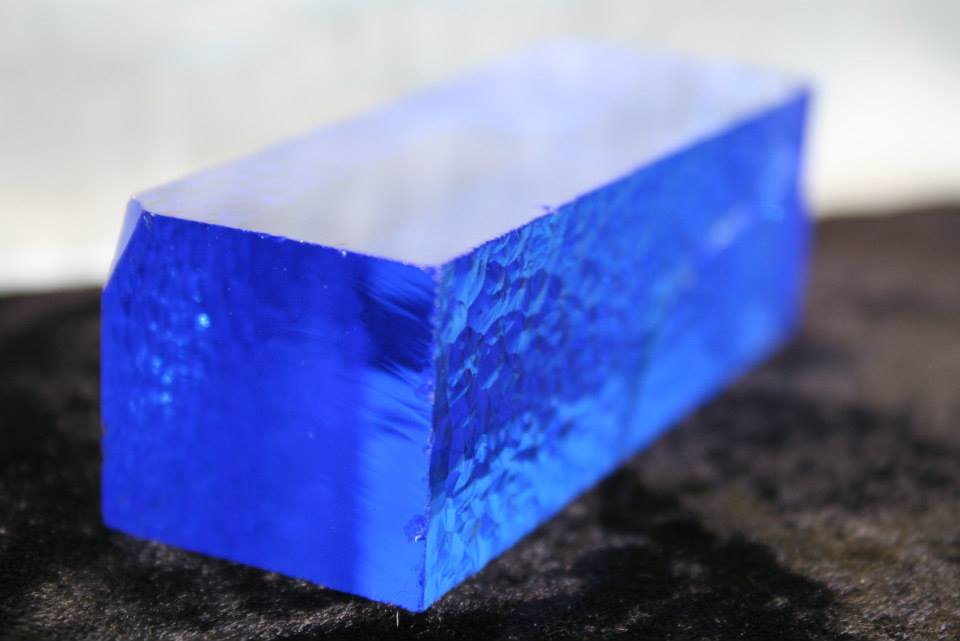

Technical specification for colored quartz.

| № | Name of item | citrine | green | blue | amethyst | smoky |

| 1. | Crystal’s dimensions along axis, mm | |||||

| Z (Y’), not less | 25 | 25 | 25 | 23 | 25 | |

| Y (Z’), not less | 170 | 170 | 170 | 22 | 22 | |

| X, not less | 60 | 60 | 60 | 170 | 100 | |

| 2. | Color intensity | |||||

| 2.1 | Mark – extra | КА-E | ||||

| Wave length, nm | 550 | |||||

| Optical density, not less | 1,5 | |||||

| 2.2 | Mark – 1 | КTs-1 | КZ-1 | КS-1 | КА-1 | КD-1 |

| Wave length, nm | 500 | 700 | 590 | 550 | 430 | |

| Optical density, not less | 0,8 | 1,6 | 0,5 | 1,3 | 1,3 | |

| 2.3 | Mark – 2 | КTs-2 | КZ-2 | КS-2 | КА-2 | КD-2 |

| Wave length, nm | 500 | 700 | 590 | 550 | 430 | |

| Optical density, not less | 0,15 | 0,8 | 0,1 | 1,0 | 0,4 | |

| 3. | Valid features | |||||

| 3.1 | Grade 1 | – any peculiarities in seed zone (zone – up to 5 mm), including cracks and stratifications;

– cracks in holder zone, entering the usable zone up to 10 mm; – twins without cracks; – punctures (in grown layer; from basis; from the seed); twins with cracks; petal crack in grown layer – up to 5 pcs. with depth up to 7 mm; – constricted growth, with provision the minimum thickness as in item 1; – periphery cracks with depth up to 5 mm and chips with dimension no more (10*10) mm and with depth up to 5 mm |

||||

| Grade 2 | – any peculiarities in seed zone (zone – up to 10 mm), including cracks and stratifications;

– cracks in holder zone, entering the usable zone up to 20 mm; – punctures (in grown layer; from basis; from the seed); twins with cracks; petal crack in grown layer; – constricted growth, with split cracks with provision the minimum thickness as in item 1; – cracks in usable zone, including split ones – up to 3 pcs. |

|||||

| Grade 3 | – cracks in holder zone, entering usable zone up to 50% in volume;

– cracks in usable zone, including split ones – up to 6 pcs. – crystal’s minimum length reduction as per item 1 by 20 mm |

|||||

| 4. | Marking | Crystals are marked with paper label with indication batch No. | ||||

| 5. | Packing | Packing should protect crystals from any damages during transportation. | ||||

Technical Specification for Synthetic Quartz lumbered bars.

All quality tests of quartz from which the lumbered bars are produced

are made according to IEC 60758(2016) Standard

1. Modification: Right-Hand.

2. Q-value Q >= 1,8 x106

3. Etch channel density :

| Grade | Etch channel density, pcs./cm2 |

| 1 | 10 |

| 2 | 30 |

| 3 | 100 |

| 4 | 300 |

4. Inclusions density

| Grade | Inclusions density, no more, pcs./cm3 | |||

| (10-30) mkm | >(30-70) mkm | >(70-100) mkm | > 100 mkm | |

| Ib | 3 | 2 | 1 | 1 |

| I | 6 | 4 | 2 | 2 |

| II | 9 | 5 | 4 | 3 |

5. Dimensions. Specified when ordering

6. Orientation:

-

- «Z»surfaces towards axes «X» and «Y» – +/-15 min,

- «-X» surface towards axes «Z» and«Y» – +/-10 min.

7. Lumbered bar should not have twins and cracks.

8. Lumbered bars may have peculiarities, specified additionally before ordering.

9. Roughness of finished surfaces Ra no more 2,5.

10.Flatness of «Х» and «Z» surfaces no more than 0,05 mm.

11.Nonparallelism of «Х» surfaces no more than 0,2 mm.

12.Seed should be in the central part of lumbered bar within zone 3,5 mm; Z seed < 2,5 mm.

13.Marking. Specified additionally before ordering

14.Packing. Bars are packed in a way that packing should protect them from any damages during transportation

Technical specification for chemically pure quartz. .

1. Z dimension is no more than 60 mm;

2. The content of impurity elements should not exceed the following indicators, ppm:

| Al | 5.0 |

| Ca | 0.6 |

| Mg | 0.1 |

| Fe | 0.5 |

| Na | 2.5 |

| K | 0.5 |

| Li | 2.0 |

| Ti | 0.4 |

| Cr, Cu, V, Mn, Ni. | 0.1 |

3. Quartz crystals may have remains of metal holder inside.